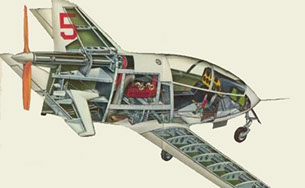

The BD-1 was the second aircraft designed by Jim Bede Sr., even though its conception started well before the project was underway. The original goal of the BD-1 design was to produce an all metal replacement for the J3 cub. It was intended to be a very low cost aircraft powered by a 65 HP engine. Some other unique design features that were incorporated to reduce the manufacturing cost were as follows:

Because of the components’ similarities, a dealer could keep lower inventories of parts, thus creating a more economically affordable aircraft for the customer. As the demand for a more sophisticated and powerful aircraft rose, an alternate power source to the original engine was introduced, the 108 HP Lycoming engine. In the first 1,000 orders, the new 108 HP engine proved to be very popular, and would set the success of the BD-1 into motion. The company sold the plane, direct from the factory, at a price of $4,900.

The growth in popularity for the company attracted an influx of new investors. The company changed its name from Bede Aviation to American Aviation and the aircraft changed as well from the BD-1 to the American Yankee.

Because of the components’ similarities, a dealer could keep lower inventories of parts, thus creating a more economically affordable aircraft for the customer. As the demand for a more sophisticated and powerful aircraft rose, an alternate power source to the original engine was introduced, the 108 HP Lycoming engine. In the first 1,000 orders, the new 108 HP engine proved to be very popular, and would set the success of the BD-1 into motion. The company sold the plane, direct from the factory, at a price of $4,900.The growth in popularity for the company attracted an influx of new investors. The company changed its name from Bede Aviation to American Aviation and the aircraft changed as well from the BD-1 to the American Yankee.

A humorous anecdote surrounding and ex-Cessna engineer occurred when he indicated that the inlet for the carburetor should be altered from the scope to where the filter was adjacent to the cowling surface. The aircraft lost 6 MPH and had a noticeable decrease in manifold pressure. The engineer blamed it on Continental engine data, which ironically occurred at Cessna prior to the alteration of the BD-1. The American Aviation company was purchased by

Grumman Aircraft and the operation moved from Cleveland, Ohio to Savannah, Georgia. The Yankee spawned the development of several excellent, four place aircrafts, as well as a light twin. The quality of manufacturing was always excellent and still holds true to this day.

Crew: 1

Capacity: 1 passenger

Length: 18 ft 6 in (5.64 m)

Wingspan: 23 ft 0 in (7.01 m)

Height: 6 ft 3.5 in (1.918 m)

Wing area: 93.3 sq ft (8.67 m2)

Airfoil: NACA 642415

Empty weight: 832 lb (377 kg)

Max takeoff weight: 1,375 lb (624 kg)

Fuel capacity: 25 US Gallons (94.5 L)

Powerplant: 1 × Lycoming O-235-C1 air-cooled flat-four, 108 hp (81kW)

Maximum speed: 155 mph (249 km/h; 135 kn) at sea level

Cruise speed: 135 mph (117 kn; 217 km/h) (econ cruise)

Stall speed: 52 mph (45 kn; 84 km/h) (flaps down)

Never exceed speed: 251 mph (218 kn; 404 km/h)

Range: 600 mi (521 nmi; 966 km)

Service ceiling: 18,000 ft (5,486 m)

Rate of climb: 1,150 ft/min (5.8 m/s)